In industrial and manufacturing operations, machine performance has a direct impact on productivity, cost control, and workflow efficiency. Two of the most essential metrics for evaluating equipment reliability are uptime and availability. Understanding how these metrics function, and applying strategies to optimize them, can significantly benefit an organization’s operational output.

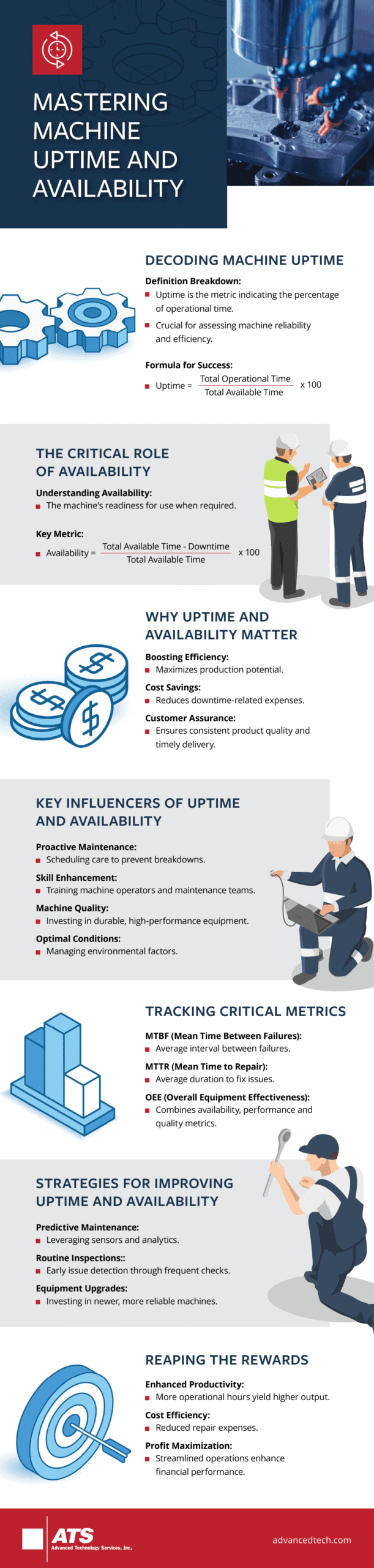

Machine uptime refers to the amount of time equipment is fully operational and functioning as intended. It provides a clear picture of how reliable and efficient a machine is under real-world conditions. When uptime is high, interruptions are minimal and production continues smoothly. Achieving this requires consistent maintenance, experienced operators, and durable, well-engineered equipment.

Availability, while closely related, captures a broader perspective. It considers not only how long a machine is working, but how long it remains ready to work when needed. Even if a machine is not currently running, it must be prepared for immediate use to avoid causing hold-ups in the production cycle. This measure helps assess the equipment’s readiness and responsiveness to demand.

The value of high uptime and availability is seen throughout the operation. Reliable machinery allows for smoother production planning, fewer delays, and more predictable outcomes. Teams are able to meet deadlines, control costs associated with downtime, and maintain the quality standards customers expect. These improvements contribute directly to customer satisfaction and long-term profitability.

Several factors influence these performance metrics. Preventive maintenance is one of the most effective ways to avoid unexpected equipment failures. By scheduling routine service, inspecting components, and replacing parts before they break down, businesses reduce unplanned interruptions and extend equipment life. Proactive care keeps machines running consistently and reduces emergency repair costs.

The knowledge and training of your workforce also play a crucial role. Skilled operators and technicians are more likely to recognize early signs of wear, misuse, or malfunction. With their insight, issues can be addressed before they lead to full-scale equipment failure. Well-trained staff also improve the overall safety and efficiency of the operation.

Equipment quality itself cannot be overlooked. Machines built for durability and engineered with maintenance in mind are less likely to fail unexpectedly. Newer models often include monitoring capabilities and diagnostic features that simplify troubleshooting and support proactive servicing. Environmental conditions, including temperature, humidity, and dust levels, should also be monitored, as they can negatively affect performance if not properly controlled.

Tracking uptime and availability effectively often involves the use of key maintenance metrics. Mean Time Between Failures (MTBF) measures the average duration a machine operates before experiencing a breakdown, while Mean Time to Repair (MTTR) calculates how long it typically takes to restore function after a failure. These indicators provide critical insights into equipment reliability and the responsiveness of the maintenance process.

More advanced organizations may also implement predictive maintenance techniques. By using data collected from sensors and performance monitoring tools, teams can detect subtle changes in machine behavior that signal a potential issue. With this information, maintenance can be scheduled before failure occurs, preventing downtime and improving the long-term performance of assets.

In conclusion, prioritizing uptime and availability supports a more resilient and efficient operation. Through a combination of regular maintenance, skilled staff, high-quality equipment, and smart use of data, businesses can reduce delays, lower costs, and achieve greater consistency in their production processes. For more on this, check out the accompany resource from Advanced Technology Services, a provider of industrial maintenance training.